- ← Previous item

- Pos.-No. 23207721

- Next item →

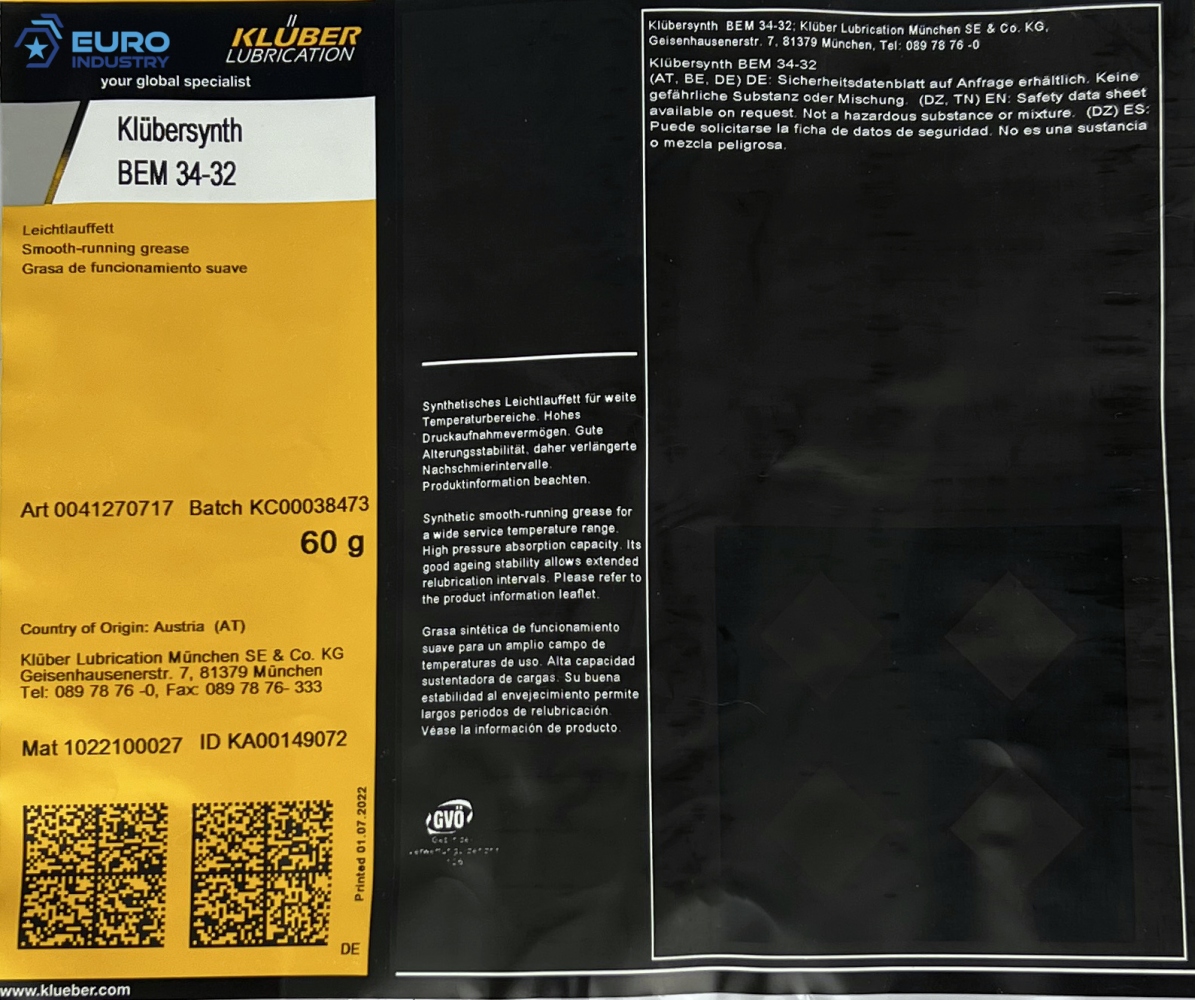

Klübersynth BEM 34-32 Synthetic smooth-running grease 60g cartridge

Klübersynth BEM 34-32 Synthetic smooth-running grease 60g cartridge

€ 59.44 59.44 incl. VAT (49.95 excl. VAT), per piece *

Availability: Available

Packaging unit: 1 piece

Manufacturer: KLUBER

Country of origin: AT/0038

Customs tariff number: 34039900

Weight per piece: 80 g

Please give the recipient email address, as well as your name and email address.

The product description does not help you?

No problem. Simply fill out the form and we will answer you as soon as possible.

No problem. Simply fill out the form and we will answer you as soon as possible.

Synthetic smooth-running grease for linear guides and bearings in clean room production areas

- Klübersynth BEM 34-32 is a special high pressure, synthetic, smooth-running grease for use across a wide service temperature range. Its excellent ageing stability allows

extended relubrication intervals or lifetime lubrication to be accomplished - Content: 60g cartridge

- Available in 50g tube, 60g cartridge, 400g cartridge

Benefits for your application

- enables low starting and running torque

- high pressure absorption capacity

- good wear protection

- excellent oxidation and ageing stability

- good water and media resistance

Application

- PARALIQ 91 is used as release agent for baking tins and moulds in the food-processing industry. The lubricant can also be used as high-performance needle and sinker oil in textile machines as well as for deep-drawing or bending of packages for the pharmaceutical and foodprocessing industries

- This special oil is tried-and-tested as release agent for moulds in blister machines used for the deep-drawing of film (bottom film)

Application note

- The low base oil viscosity of Klübersynth BEM 34-32 ensures smooth running of linear guides, ball bushings, ball screws, rolling bearings, plain bearings as well as small gear systems in all sectors which are not subject to high vacuum, high temperatures or aggressive media. Due to the excellent metal adhesion properties, Klübersynth BEM 34-32 achieves

considerably lower wear rates than many PFPE-based greases used under similar application conditions. The product is compatible with most plastic seals and cage materials

Technical specifications

| Article number | 4127 |

| Chemical composition, thickener | special calcium soap |

| Chemical composition, type of oil | synthetic hydrocarbon oil |

| Lower service temperature | -40 °C / -40 °F |

| Upper service temperature | 130 °C / 266 °F |

| Colour space | beige |

| Texture | short-fibred |

| Texture | homogeneous |

| Worked penetration, DIN ISO 2137, 25 °C, lower limit value | 265 x 0,1 mm |

| Worked penetration, DIN ISO 2137, 25 °C, upper limit value | 295 x 0,1 mm |

| Kinematic viscosity of the base oil, DIN 51562 pt. 01/ASTM D-445/ASTM D 7042, 40 °C | approx. 31 mm²/s |

| Kinematic viscosity of the base oil, DIN 51562 pt. 01/ASTM D-445/ASTM D 7042, 100 °C | approx. 5,9 mm²/s |

| NLGI grade, DIN 51818 | 2 |

| Speed factor (n x dm) | approx. 1 000 000 mm/min |

| Shear viscosity at 25 °C, shear rate 300 s-1, equipment: rotational viscometer, lower limit value | 2 800 mPas |

| Shear viscosity at 25°C, shear rate 300 s-1, equipment:rotational viscometer, upper limit value | 5 200 mPas |

| Corrosion inhibiting properties of lubricating greases, DIN 51802, (SKF-EMCOR), test duration: 1 week, distilled water | <= 1 corrosion degree |

| Drop point, DIN ISO 2176, IP 396 | >= 220 °C |

| Water resistance, DIN 51807 pt. 01, 3 h/90 °C, rating | 1 - 90 |

| Minimum shelf life from the date of manufacture - in a dry, frost-free place and in the unopened original container, approx. | 36 months |

KLÜBER LUBRICATION MÜNCHEN GMBH & CO. KG, Geisenhausenerstraße 7, 81379 München, GERMANY, +49 89 7876 0, [email protected], www.klueber.com

| Property | GTIN/EAN | MPN (Manufacturer Part Number) |

|---|---|---|

| - | - | 943150592 |

* Price in Euro including VAT, plus forwarding charges.

In parentheses: price in Euro excluding VAT, plus forwarding charges.

Clients outside the EU as well as companies outside of Germany don't pay any VAT (excepting for shipping in Germany)!

English

English  Français

Français Deutsch

Deutsch

Follow us