- ← Previous item

- Pos.-No. 23204763

- Next item →

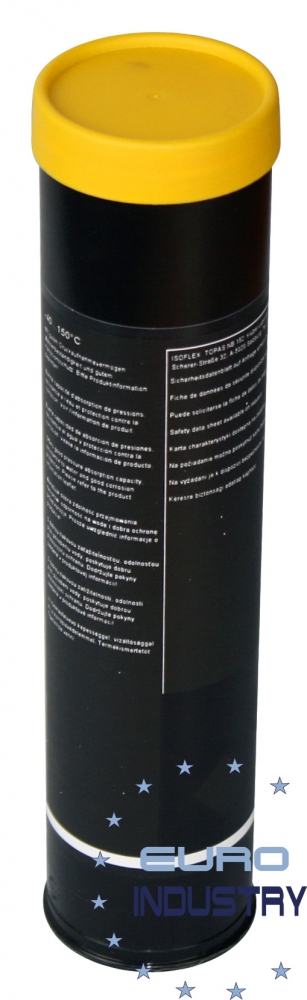

Klüber Topas NB 152 Synthetic rolling and plain bearing grease 400g

Klüber Topas NB 152 Synthetic rolling and plain bearing grease 400g

€ 142.74 142.74 incl. VAT (119.95 excl. VAT), per piece *

Availability: Available

Packaging unit: 1 piece

Manufacturer: KLUBER

Country of origin: AT/0038

Customs tariff number: 34031980

Weight per piece: 450 g

Please give the recipient email address, as well as your name and email address.

The product description does not help you?

No problem. Simply fill out the form and we will answer you as soon as possible.

No problem. Simply fill out the form and we will answer you as soon as possible.

ISOFLEX TOPAS NB 52 and ISOFLEX TOPAS NB 152 are rolling and plain bearing greases based on a synthetic hydrocarbon oil and a barium complex soap. The special barium-soap thickener used in the ISOFLEX TOPAS NB 52 and 152 greases offers good load-carrying capacity as well as resistance to water and ambient media unlike other soap-based thickeners. Both products show good protection against corrosion as well as oxidation and ageing stability. The Klüber barium complex soap is ELINCS-registered and approved by GASG (Global Automotive Stakeholders Group).

ISOFLEX TOPAS NB52 is suitable for temperatures between -50 °C to 120 °C and short peak temperatures up to 150 °C depending on the application, e.g. enclosed gears, car seat adjustment mechanisms.

Benefits for your application:

- Longer component life when exposed to water or aqueous media due to special thickener

- Many years of successful use in the automotive and machine building industries

Application:

ISOFLEX TOPAS NB 52 is a versatile grease for many applications, e.g.

- Rolling and plain bearings subject to high speeds and loads, also for low temperatures,

- Tooth flanks in precision gears, e.g. bevel gears in milling machines, electromechanical actuators for valves,

- Electric contacts and components to reduce insertion forces.

Application notes:

The greases are applied by spatula, brush, grease gun or cartridge. Sprays should not be exposed to direct sunlight and temperatures above 50 °C.

Product data:

| Lower service temperature | -50 °C / -58 °F |

| Upper service temperature | 120 °C / 248 °F |

| Color space | beige |

| Texture | homogeneous |

| Texture | short-fibred |

| Density at 20 °C | approx. 0.96 g/cm³ |

| Worked penetration, DIN ISO 2137, 25 °C, lower limit value | 265 x 0.1 mm |

| Worked penetration, DIN ISO 2137, 25 °C, upper limit value | 295 x 0.1 mm |

| Kinematic viscosity of the base oil, DIN 51562 pt. 01/ASTM D-445/ASTM D 7042, 40 °C | approx. 30 mm²/s |

| Kinematic viscosity of the base oil, DIN 51562 pt. 01/ASTM D-445/ASTM D 7042, 100 °C | approx. 5.9 mm²/s |

| Shear viscosity at 25 °C, shear rate 300 s-1, equipment: rotational viscometer, lower limit value | 4 000 mPas |

| Shear viscosity at 25°C, shear rate 300 s-1, equipment:rotational viscometer, upper limit value | 8 000 mPas |

| Corrosion inhibiting properties of lubricating greases, DIN51802, (SKF-EMCOR), test duration: 1 week, distilled water | 0 corrosion degree |

| Copper corrosion, DIN 51811, (lubricating grease), 24h/100°C | 1 - 100 corrosion degree |

| Oil separation, ASTM D 6184 [FTMS 791 C 321], after 30h/100 °C | <= 3 % by weight |

| Drop point, DIN ISO 2176 | >= 240 °C |

| Oxidation stability of lubricating greases, ASTM D942, 100 h/99 °C, pressure drop | <= 0.3 bar |

| Speed factor (n x dm) | approx. 1 000 000 mm/min |

| Water resistance, DIN 51807 pt. 01, 3 h/90 °C, rating | <= 1 - 90 |

| Minimum shelf life from the date of manufacture - in a dry, frostfree place and in the unopened original container, approx. | 36 months |

KLÜBER LUBRICATION MÜNCHEN GMBH & CO. KG, Geisenhausenerstraße 7, 81379 München, GERMANY, +49 89 7876 0, [email protected], www.klueber.com

| Property | GTIN/EAN | MPN (Manufacturer Part Number) |

|---|---|---|

| - | 0725175312443 | 943150266 |

* Price in Euro including VAT, plus forwarding charges.

In parentheses: price in Euro excluding VAT, plus forwarding charges.

Clients outside the EU as well as companies outside of Germany don't pay any VAT (excepting for shipping in Germany)!

English

English  Français

Français Deutsch

Deutsch

Follow us