- ← Previous item

- Pos.-No. 23211778

- Next item →

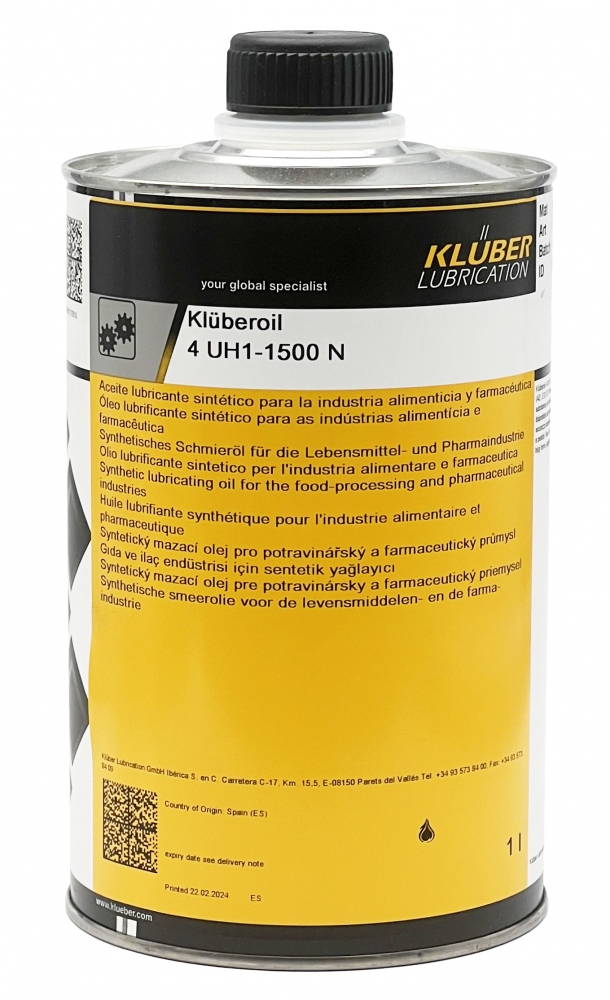

Klüberoil 4 UH1-1500 N Synthetic gear and multipurpose oil 1L

Klüberoil 4 UH1-1500 N Synthetic gear and multipurpose oil 1L

€ 127.27 127.27 incl. VAT (106.95 excl. VAT), per piece *

Availability: Available

Packaging unit: 1 piece

Manufacturer: Klüber

Country of origin: ES/0011

Customs tariff number: 34039900

Weight per piece: 1.0 kg

Please give the recipient email address, as well as your name and email address.

The product description does not help you?

No problem. Simply fill out the form and we will answer you as soon as possible.

No problem. Simply fill out the form and we will answer you as soon as possible.

Synthetic gear and multipurpose oil

- Klüberoil 4 UH1-1500 N Spray is a synthetic high-performancegear and multipurpose oil based on polyalphaolefin satisfyinthe growing requirements and increasing power densities.Klüberoil 4 UH1-1500 N Spray is based on high-grade rawmaterials and advanced additives, enabling maximum performance.

- Klüberoil 4 UH1-1500 N Spray is registered as NSF H1 for usein the food-processing and pharmaceutical industries andcomplies with FDA 21 CFR Sec 178.3570. It was developed for incidental contact with products and packaging materials in the food-processing, cosmetics, pharmaceutical or animal feed industries. The use of Klüberoil 4 UH1-1500 N Spray can contribute to increase reliability of your production processes. Nevertheless it is recommended to conduct an additional risk analysis, e.g. HACCP.

- Gears are sufficiently protected against scuffing even at extremely high peak loads, vibrations or oscillations, or if no running-in was performed. The good wear protection of both gears and rolling bearings ensures that the service life calculated for the lubricated components is achieved, leading to lower maintenance and repair costs.

- Klüberoil 4 UH1-1500 N Spray offers a much longer service life than mineral and white oils due to the excellent ageing and oxidation resistance of the selected raw materials; thus service intervals can be extended and maintenance costs reduced. The product's good anti-corrosive properties enable problem-free gear operation.

- The good viscosity-temperature behaviour supports the formation of a sufficient lubricant film across a wide service temperature range, even at elevated and high temperatures.

- The optimised friction behaviour enabled by the carefully selected base oils reduces power loss and improves efficiency of your application.

- By using Klüberoil 4 UH1-1500 N Spray you can benefit from a number of advantages that will help you save costs easily and efficiently. We look forward to hearing from you.

- Size: 1L

Benefits for your application:

- Registered as NSF H1

- High scuffing protection

- Good wear protection for gears and rolling bearings

- Good shear stability for reliable lubricant film formation

- Excellent ageing and oxidation resistance

- Wide service temperature range due to good viscosity-temperature behaviour

- Low foaming tendency

- Energy savings due to optimised friction behaviour

- Good elastomer compatibility

Application:

- Klüberoil 4 UH1-1500 N Spray was developed for thelubrication of spur, bevel and worm gears subject to high loads,bearings, spindles, joints as well as lifting, drive and transport chains.

Application notes:

- Klüberoil 4 UH1-1500 N Spray is miscible with mineral oils andsynthetic hydrocarbons. Prior to switchover, lubrication points should be cleaned. In view of the H1 requirements in the foodprocessing industry, any mixture with non-H1 lubricants during conversion has to be prevented.

- Shake well before use. Ensure sufficient ventilation during spraying as explosive mixtures may form. Do not spray against nake flame or onto hot incandescent objects. Observe additional instructions for use in material

safety data sheet and on can label.

Product data:

| Article number | 81263 |

| NSF-H1 registration | 130 064 |

| Upper service temperature | 120 °C / 248 °F |

| Density, based on DIN 51757) at 15 °C | approx. 866 kg/m³ |

| Kinematic viscosity, DIN 51562 pt. 01/ASTM D-445/ASTM D 7042, 40 °C | approx. 1 500 mm²/s |

| Kinematic viscosity, DIN 51562 pt. 01/ASTM D-445/ASTM D 7042, 100 °C | approx. 125 mm²/s |

| Viscosity index, DIN ISO 2909 | >= 180 |

| ISO viscosity grade, DIN ISO 3448 | 1 500 |

| Anticorrosive properties on steel, DIN ISO 7120, method A, steel, 24 h/60 °C | no rust corrosion degree |

| Copper corrosion, DIN EN ISO 2160, 24 h/100°C | 1 - 100 corrosion degree |

| Ageing properties, ASTM D 2893, increase in viscosity | <= 6 % |

| FAG FE8 rolling bearing test, DIN 51819-3, D 7,5/80-80, wear of cage | <= 200 mg |

| FAG FE8 rolling bearing test, DIN 51819-3, D 7,5/80-80, wear of rolling element | <= 30 mg |

| Flash point, DIN EN ISO 2592, Cleveland, open-cup apparatus | >= 200 °C |

| FZG scuffing test, DIN ISO 14635-1, A/8.3/90, scuffing load stage | >= 12 |

| Pour point, DIN ISO 3016 | <= -25 °C |

| Minimum shelf life from the date of manufacture - in a dry, frost-free place and in the unopened original container, approx. | 36 months |

KLÜBER LUBRICATION MÜNCHEN GMBH & CO. KG, Geisenhausenerstraße 7, 81379 München, GERMANY, +49 89 7876 0, [email protected], www.klueber.com

| Property | GTIN/EAN | MPN (Manufacturer Part Number) |

|---|---|---|

| - | - | 100146179 |

* Price in Euro including VAT, plus forwarding charges.

In parentheses: price in Euro excluding VAT, plus forwarding charges.

Clients outside the EU as well as companies outside of Germany don't pay any VAT (excepting for shipping in Germany)!

English

English  Français

Français Deutsch

Deutsch

Follow us