- ← Vorheriger Artikel

- Art.Nr. 23209839

- Nächster Artikel →

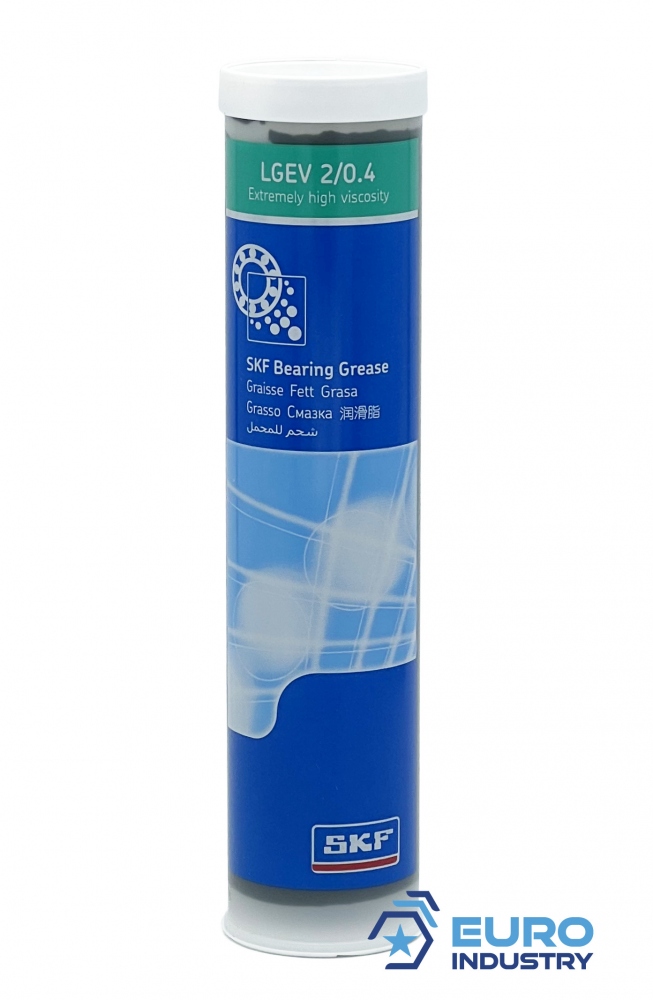

SKF LGEV 2/0.4 Wälzlagerfett extrem hochviskos 420ml Kartusche

€ 20.17 20,17 inkl. MwSt. (16,95 exkl. MwSt.), pro Stück *

Verfügbarkeit: Verfügbar

Verpackungseinheit: 1 Stück

Hersteller: SKF GmbH

Ursprungsland: DE/0004

Zolltarifnummer: 27101999

Gewicht pro Stück: 450 g

Kein Problem. Füllen Sie einfach das Formular aus und wir beantworten Ihnen so schnell wie möglich ihre Anfrage.

Extrem hochviskoses SKF Wälzlagerfett mit Festschmierstoff-Zusätzen

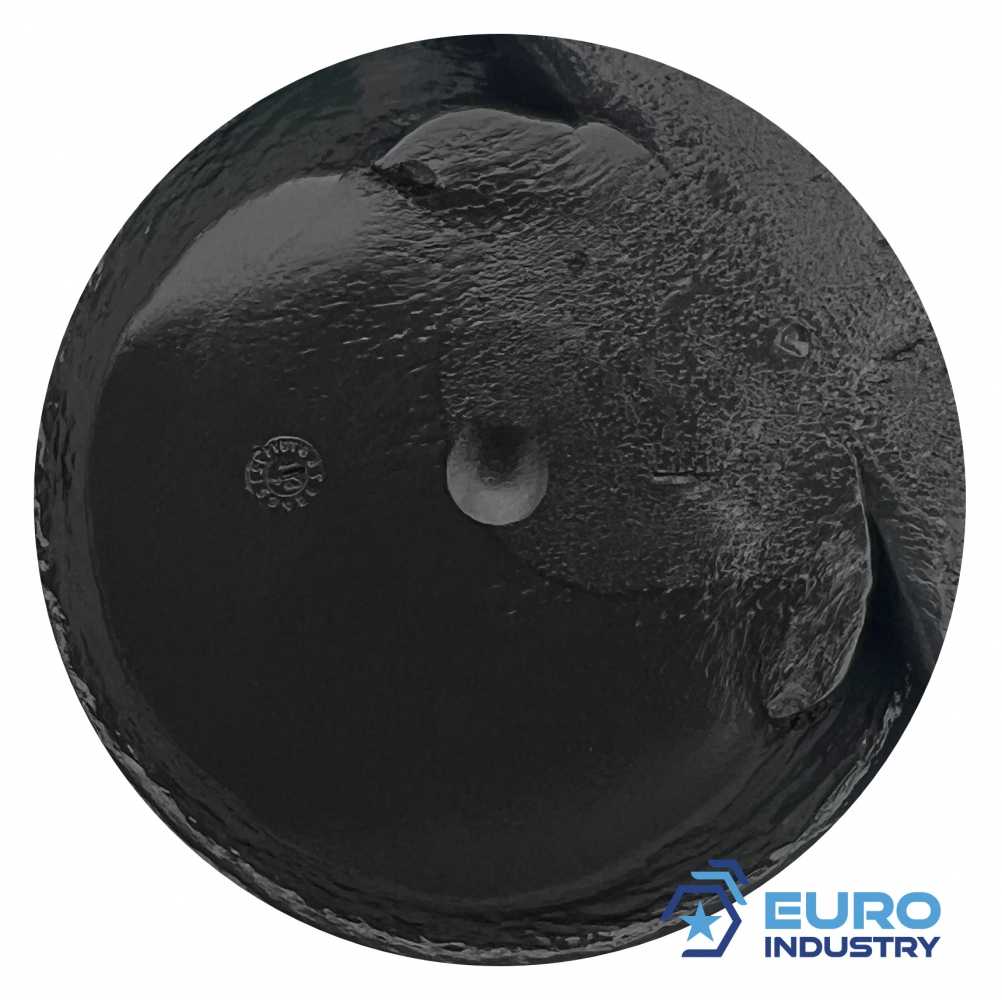

SKF LGEV 2 ist ein Lithium-Kalzium verseiftes Fett auf Mineralölbasis. Es hat einen hohen Gehalt an Molybdändisulfid und Graphit, kombiniert mit einem extrem hochviskosen Öl. Dadurch wird ein herausragender Schutz auch bei rauesten Bedingungen gewährleistet (hohe Belastungen, niedrige Drehzahlen und hohe Schwingungspegel).

Merkmale

- Ausgezeichnete Eignung für das Schmieren großer Pendelrollenlager, die hohen Belastungen bei niedrigen Drehzahlen ausgesetzt sind (d.h. hohes Mikroschlupfrisiko)

- Mechanisch extrem stabil; gutes Verhalten gegenüber Wasser und guter Korrosionsschutz

- Inhalt: 420 ml Kartusche

- Auch erhältlich als Tube 35 g, Kartusche 420 ml, Dose 5 kg, Eimer 18 kg, Fass 50 kg, Fass 180 kg

Typische Anwendungsfälle

- Zapfenlager für umlaufende Trommeln

- Stützrollen und Druckrollen von Drehöfen und Trocknern

- Schaufelradbagger

- Drehkranzlager

- Hochdruck-Rollwalzen

- Brecher

Technische Daten

Kurzzeichen |

| LGEV 2/(Gebindegröße) |

DIN 51825 Bezeichnung |

| KPF2K-10 |

NLGI-Penetrationsklasse |

| 2 |

Verdicker |

| Lithium/Kalzium |

Farbe |

| Schwarz |

Grundöltyp |

| Mineralöl |

Betriebstemperaturbereich |

| –10 bis +120 °C |

Tropfpunkt nach DIN ISO 2176 |

| >180 °C |

Grundölviskosität | 40 °C, mm²/s | 1 020 |

100 °C, mm²/s | 58 | |

Penetration nach DIN ISO 2137 | 60 Hübe, 10-1 mm | 265–295 |

100 000 Hübe, 10-1 mm | 325 max. | |

Mechanische Stabilität | Walkstabilität, 72 h bei 100 °C, 10-1 mm | +50 max. |

SKF V2F-Prüfung | ‘M’ | |

Korrosionsschutz | SKF Emcor: – ISO 11007 | 0–0 |

SKF Emcor: – Wasserausspültest | 0–0* | |

SKF Emcor: Salzwassertest (100 % Meerwasser) | 0–0* | |

Wasserbeständigkeit | DIN 51 807/1, 3 Std. bei 90 °C | 1 max. |

|

| |

Ölabscheidung | DIN 51 817, 7 Tage bei 40 °C, statisch, % | 1-5 |

|

| |

Kupferkorrosion | DIN 51 811 | Max. 2 bei 100 °C |

Verhalten bei hohen Belastungen | Schweißkraft nach DIN 51350/5, 1.400 N, mm | 1,2 max. |

4–Kugel Test, Schweißkraft nach DIN 51350/4, N | 3.000 min. | |

Lagerfähigkeit |

| 5 Jahre |

SKF GmbH, Gunnar-Wester-Straße 12, 97421 Schweinfurt, GERMANY, +49 9721 56-0, [email protected], www.skf.com

| Eigenschaft | GTIN/EAN | MPN (Manufacturer Part Number) |

|---|---|---|

| - | 7316571591988 | 967000102 |

* Preis in Euro inklusive gesetzlicher Mehrwertsteuer, zzgl. Versandkosten.

In Klammern: Preis in Euro exklusive gesetzlicher Mehrwertsteuer, zzgl. Versandkosten.

Kunden außerhalb der EU sowie Firmen außerhalb von Deutschland zahlen keine MwSt. (ausgenommen Lieferung nach Deutschland)!

Deutsch

Deutsch  English

English Français

Français

Folgen Sie uns