- ← Previous item

- Pos.-No. 23211529

- Next item →

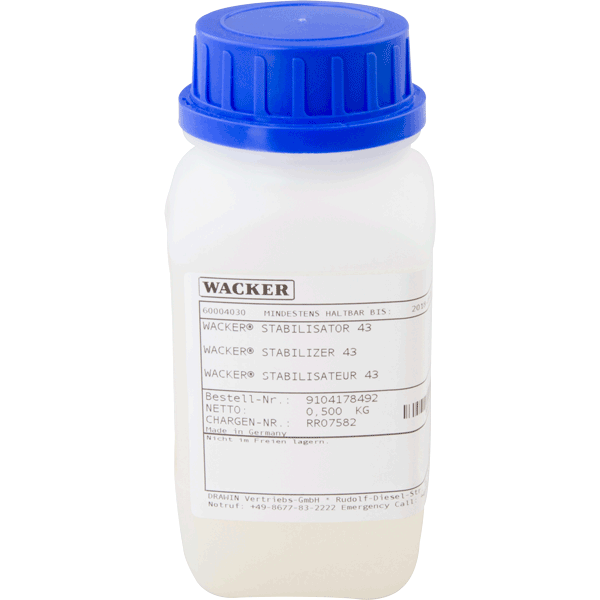

Wacker STABILIZER 43 silicone rubber RTV-2 mold making 0.5kg/can

Wacker STABILIZER 43 silicone rubber RTV-2 mold making 0.5kg/can

€ 45.16 45.16 incl. VAT (37.95 excl. VAT), per piece *

Availability: shipping in 3-5 working days

Packaging unit: 1 piece

Manufacturer: Wacker

Country of origin: DE/0004

Customs tariff number: 32141010

Weight per piece: 600 g

Please give the recipient email address, as well as your name and email address.

The product description does not help you?

No problem. Simply fill out the form and we will answer you as soon as possible.

No problem. Simply fill out the form and we will answer you as soon as possible.

WACKER® STABILIZER 43 - RTV-2 SILICONE RUBBER / MOLD MAKING

Product description

This additive is used to thicken or render non-sag those grades of the ELASTOSIL® M "46.." high-strength series which are flowable as supplied. The

effect is such that, when - for example - a skin mold is being made, the silicone rubber can be applied even to inclined or vertical surfaces by brush or spatula without flowing off or sagging.

The more additive added to the rubber mass, the thicker tem mass becomes.

Thus, the whole range of thixotropic states can be attained, including the fully non-sag state.

WACKER® STABILIZER 43 is a colorless, cloudy,medium-viscosity liquid with a faint odor.

It is exclusively used to thicken those addition-curing RTV-2 silicone rubber grades of the "ELASTOSIL® M 46 .." series which are flowable as supplied.

Processing

Addition of 0.3 - 0.5 wt % of WACKER® STABILIZER 43 (the exact proportion depending on the grade of rubber) confers excellent non-sag properties on the

catalyzed mix, at least for layers of up to 10 mm thickness, when applied to vertical surfaces.

We recommend the following procedure for mixing in the additive as homogeneously as possible:

1. Weigh out the silicone rubber base or Component A

2. Add the required proportion of Catalyst or Component B

3. Mix the mass thoroughly

4. Weigh out and add the additive

5. Mix the mass thoroughly

When small quantities of silicone rubber are processed, the additive is best added via a disposable pipette (20 drops ≈ 1 g).

Storage

The 'Best use before end' date of each batch is shown on the product label.

Storage beyond the date specified on the label does not necessarily mean that the product is no longer usable. In this case however, the properties required

for the intended use must be checked for quality assurance reasons

Product description

This additive is used to thicken or render non-sag those grades of the ELASTOSIL® M "46.." high-strength series which are flowable as supplied. The

effect is such that, when - for example - a skin mold is being made, the silicone rubber can be applied even to inclined or vertical surfaces by brush or spatula without flowing off or sagging.

The more additive added to the rubber mass, the thicker tem mass becomes.

Thus, the whole range of thixotropic states can be attained, including the fully non-sag state.

WACKER® STABILIZER 43 is a colorless, cloudy,medium-viscosity liquid with a faint odor.

It is exclusively used to thicken those addition-curing RTV-2 silicone rubber grades of the "ELASTOSIL® M 46 .." series which are flowable as supplied.

Processing

Addition of 0.3 - 0.5 wt % of WACKER® STABILIZER 43 (the exact proportion depending on the grade of rubber) confers excellent non-sag properties on the

catalyzed mix, at least for layers of up to 10 mm thickness, when applied to vertical surfaces.

We recommend the following procedure for mixing in the additive as homogeneously as possible:

1. Weigh out the silicone rubber base or Component A

2. Add the required proportion of Catalyst or Component B

3. Mix the mass thoroughly

4. Weigh out and add the additive

5. Mix the mass thoroughly

When small quantities of silicone rubber are processed, the additive is best added via a disposable pipette (20 drops ≈ 1 g).

Storage

The 'Best use before end' date of each batch is shown on the product label.

Storage beyond the date specified on the label does not necessarily mean that the product is no longer usable. In this case however, the properties required

for the intended use must be checked for quality assurance reasons

No files available for download

| Property | GTIN/EAN | MPN (Manufacturer Part Number) |

|---|---|---|

| - | - | 2188800500 |

* Price in Euro including VAT, plus forwarding charges.

In parentheses: price in Euro excluding VAT, plus forwarding charges.

Clients outside the EU as well as companies outside of Germany don't pay any VAT (excepting for shipping in Germany)!

English

English  Français

Français Deutsch

Deutsch

Follow us